This week at RS Motor engine maintenance service, a new reconditioning job of cogeneration engine components has been carried out. This time, it’s a gas mixing valve for Deutz MWM engines.

DEUTZ MWM ENGINES MAINTENANCE

At RS Motor, we understand the importance of maintaining Deutz MWM TCG and TBG cogeneration engines in optimal condition. An essential part of preventive maintenance for these types of engines is the refurbishment of gas mixers, a process that can make a difference in equipment performance and efficiency.

At RS Motor, we understand the importance of maintaining Deutz MWM TCG and TBG cogeneration engines in optimal condition. An essential part of preventive maintenance for these types of engines is the refurbishment of gas mixers, a process that can make a difference in equipment performance and efficiency.

What is a Gas Mixer?

Before delving into the refurbishment process, it’s important to understand what a gas mixer is. This component is crucial for the formation of the flammable gas and air mixture necessary for the efficient operation of the engines.

The gas mixer consists of a tube where the well-known Venturi effect occurs, with a narrowing where the airflow is accelerated and a subsequent widening that creates a depression that draws in the gas, creating the combustible mixture. The design only causes a slight pressure drop in the flow and, therefore, a minimal reduction in cylinder filling.

At the narrowest point, the flow reaches its maximum velocity. The depression created in a ring-shaped cavity causes the gas to mix radially into the main flow from the outside. This mixing method has the advantage that the gas-to-air ratio remains almost constant, even when the aspirated mixture changes considerably.

The mixer adjusts the gas/air ratio in the mixture and mixture volume is regulated by means of the throttle valve.

MAIN COMPONENTS OF GAS MIXING VALVES IN DEUTZ MWM ENGINES

Some of the main components of the gas mixer are:

Some of the main components of the gas mixer are:

• Gas inlet

• Air inlet

• Outlet for the gas and air mixture

• Drive shaft or belt, as in the case of the Motortech VariFuel system

• Stepper motor

• Connections for pressure regulator and measurement systems

• Flow bodies of various sizes to influence flow velocity, depending on the application

GAS MIXING VALVES RECONDITIONING PROCESS

At RS Motor, we follow a meticulous process for the refurbishment of gas mixer:

At RS Motor, we follow a meticulous process for the refurbishment of gas mixer:

• Disassembly and Inspection: We carefully disassemble the mixer and inspect each component. Teflon bands and seals are always replaced as they may lose their sealing properties over time. The proximity sensor is checked and adjusted, and the drive shaft is cleaned and thoroughly analyzed to prevent any potential operation failures.

• Internal Cleaning: We perform a thorough internal cleaning to ensure that all elements function correctly.

• Assembly and Testing: We reassemble the mixer and subject it to rigorous testing to ensure its optimal operation.

• Exterior Protection: We don’t overlook the external appearance. We apply primer and paint to protect the mixer housing.

This comprehensive process ensures that the gas mixer is restored to their best condition, promoting efficiency and reliability in cogeneration engines.

At RS Motor, we exclusively use genuine spare parts for Deutz MWM and/or OEM components in the refurbishment of gas mixer valves and in all our work, ensuring the quality and reliability of the repairs and maintenance carried out at RS Motor. Our experience and highly skilled personnel with extensive expertise in the field of gas engine repair make us competitive in this type of engine maintenance.

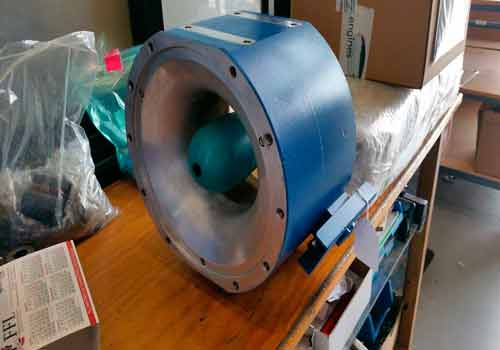

Here are some images of gas mixer valves that have undergone refurbishment in our workshop, adhering to RS Motor’s quality standards.

If you need consultations or repairs for your engine, do not hesitate to contact us. At RS Motor, we offer repair services as well as supply new and reconditioned spare parts. Our team has experience in providing reliable and professional engine repair services. We will be delighted to meet all your needs and provide the assistance you require. Feel free to get in touch with us.

For more information, you can write to social@rsmotor.es.