Recently, RS Motor completed the E70 maintenance on a Deutz Mwm TCG 2016 V16C engine. The E70 maintenance is the most comprehensive one performed on Deutz-Mwm engines and is also known as an overhaul.

Our team of specialized technicians in Guascor, Deutz Mwm, and Jenbacher engines can handle both the disassembly of the engine at the customer’s site and its connection and commissioning after the maintenance carried out at RS Motor’s facilities.

However, in this particular case, the engine was sent to RS Motor’s facilities by our client to perform the maintenance tasks. Our company also offers the flexibility to perform interventions either at our customers’ plants or vessels or at our own workshop, adapting to the specific needs and preferences of each client.

In the mentioned specific case, the client decided to send the engine without the alternator and some of the less essential components, such as the starter, filters, and ignition system. Regardless of the components sent along with the engine, RS Motor ensures that the necessary maintenance is carried out and provides a comprehensive service to guarantee optimal engine performance. Our team of specialized technicians will disassemble and inspect the engine to determine and perform the required repairs, replacements, or reconditioning.

After the disassembly, a thorough inspection of all engine components is conducted. The main repairs, replacements, or reconditioning performed were as follows:

- Inspection of the cylinder block and dimensional analysis of the crankshaft.

- Replacement of the main bearings.

- Inspection of the camshaft and replacement of the tappets.

- Replacement of the oil pump.

- Refurbishment of the pre-lubrication pump.

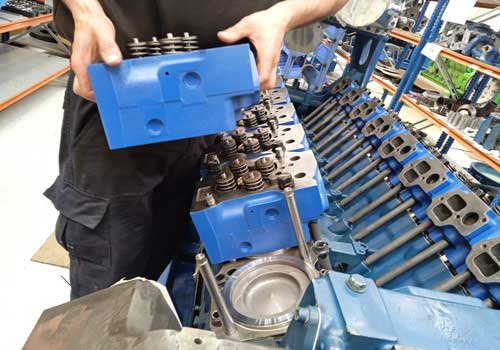

- Replacement of pistons and cylinder liners.

- Refurbishment of connecting rods, dimensional analysis, and replacement of small end and big end bearings and bolts.

- Refurbishment of cylinder heads, including machining and replacement of wear components.

- Refurbishment of the turbocharger.

- Replacement of the intercooler after cleaning and inspection deemed it useless.

- Refurbishment of the oil cooler.

- Replacement of various components of the exhaust manifold due to evidence of leaks during hydraulic testing.

- Various machining on the intake manifold to ensure proper connections.

- Replacement of the torsional vibration damper.

- Installation of a new starter.

- Replacement of some faulty ignition coils.

- Replacement of cables, gaskets, bolts, and other minor elements necessary for assembly.

- Complete engine painting.

It is worth noting that all replacement parts used are genuine Deutz Mwm spare parts and/or original OEM, ensuring the quality of the assembly and ensuring the proper functioning of the engine, thus reducing the risk of unforeseen breakdowns that may affect engine performance.

The maintenance carried out at our facilities has been completed in a short period of time thanks to RS Motor’s experience with this type of engines, minimizing plant downtime due to maintenance and increasing the productivity of our customers’ facilities.

At RS Motor, we strive to provide comprehensive and high-quality solutions for the repair and reconditioning of engines. Our meticulous approach at every stage of the repair process allows us to guarantee reliability, optimal performance, and customer satisfaction. Our commitment does not end with the delivery of the repaired engine; we offer a complete after-sales service and are available to provide technical support and advice at any time. If you are looking for reliable and professional engine repair services, please do not hesitate to contact us. We will be delighted to assist you with all your needs.

For more information, please email social@rsmotor.es.