By definition, corrective maintenance is a type of work that must be carried out as soon as possible in the event of an unscheduled engine stop due to various causes (piston seizure, high temperatures, high pressures, electronic failures …).

This is the most basic maintenance, as it simply involves repairing what has broken down. In this sense, corrective maintenance is a process that basically consists of locating and correcting faults or defects that are preventing the engine from running properly.

Corrective maintenance is a type of work that must be avoided as much as possible, since it implies that the end customer reduces the production and the operation of its power plant. The number of corrective maintenances can be decreased as long as the preventive maintenance of the engine is carried out according to the operating hours provided by the engine manufacturer, and installing quality spare parts on these.

Scheduled corrective maintenance

Scheduled corrective maintenance is a concept that is rarely applicable, although there are exceptions. Corrective maintenance is antonym of scheduling.

Whenever we talk about an intervention or scheduled work, we would be referring to the concept of preventive maintenance.

In any case, a very widespread practice nowadays is to define scheduled corrective maintenance that variant of corrective maintenance, in which the resolution of the incident that causes it, is not considered urgent nor compromises the normal operation of the power plant.

As a consequence, the scheduled corrective maintenance could consider, for example, a water or oil leak that is not serious and does not affect the normal operation of the engine.

Unscheduled corrective maintenance

As its name indicates, unscheduled corrective maintenance is the one on which unscheduled failures or breakdowns arise that make the power plant unable to operate (seizures, electrical failures…).

In unscheduled corrective maintenances, the main goal is to correct any breakdowns that occur. Therefore, all work is focused on getting the engine running as soon as possible.

Advantages and disadvantages of corrective maintenance

Although there are few, corrective maintenance can have advantages (although this is not recommended):

- Short-term costs are lower: As this type of maintenance is a reactive activity, it is only carried out when a problem occurs in the engine or in the power plant.

- Planning is minimal: Corrective maintenance consists of correcting an identified fault in a particular engine component. As a result, you don’t need to plan anything in advance.

The disadvantages of corrective maintenance are much more numerous than the advantages. We highlight the following:

- It is unpredictable: This can affect the reaction time in the event that the stock of spare parts to carry out the repair is not enough, resulting in a longer stop than is desirable.

- You will have paused operations: You never know when the engine will stop running, so availability must always be maximum and the maintenance company and plant operators must always be alert.

- Less lifespan of the equipment: Corrective maintenance does not prevent or protect the engine at all, nor does it make its useful life longer. As a conclusion, the most likely is that the engine will have to be renewed much earlier than scheduled.

- Long-term costs can be higher: When a breakdown occurs, it can become very costly now and in the future. This can be detrimental to the company’s reputation, customer satisfaction, and plant safety. In addition to the above, it would be impossible to plan any type of annual expense or manage purchases or production efficiently.

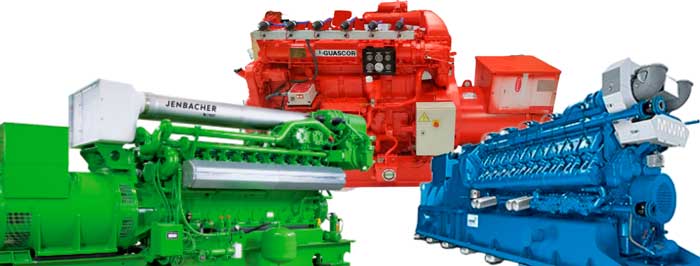

Corrective maintenance service for gas and diesel cogeneration engines

Nowadays, with more than 150 natural gas, biogas, landfill gas, and special gas engines, RS Motor is a competitive firm with large contracts that cover the needs of its customers, and also, it is a sign of guarantee for production.

Whatever the type of engine of the main brands that RS Motor works and wherever it is located, RS Motor is capable of giving a fast, efficient and quality response. Several years of experience mean that our engineers and technicians can attend to any type of repair either “on-site” or at RS Motor’s facilities.