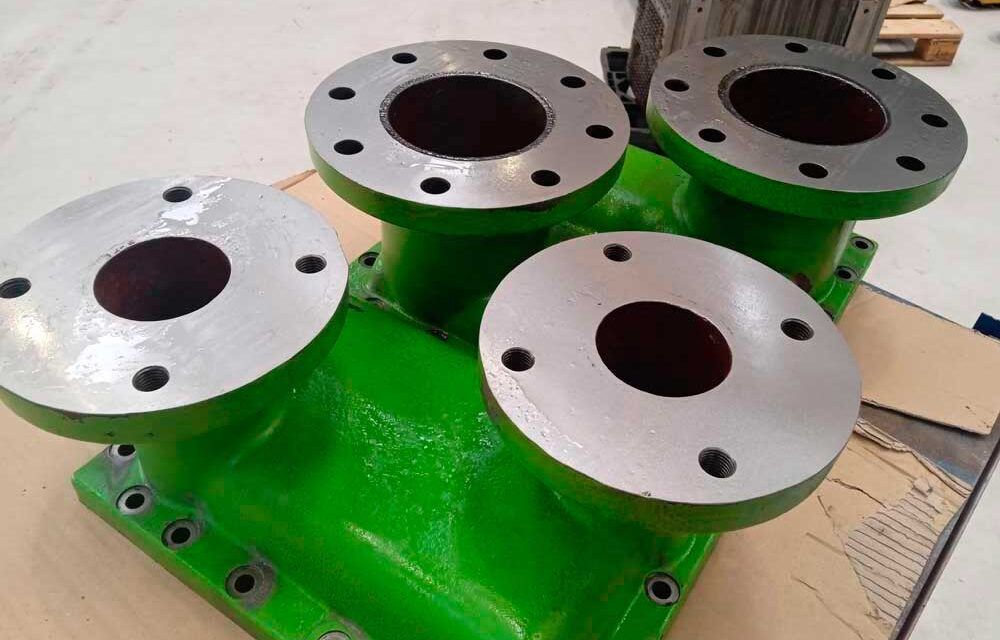

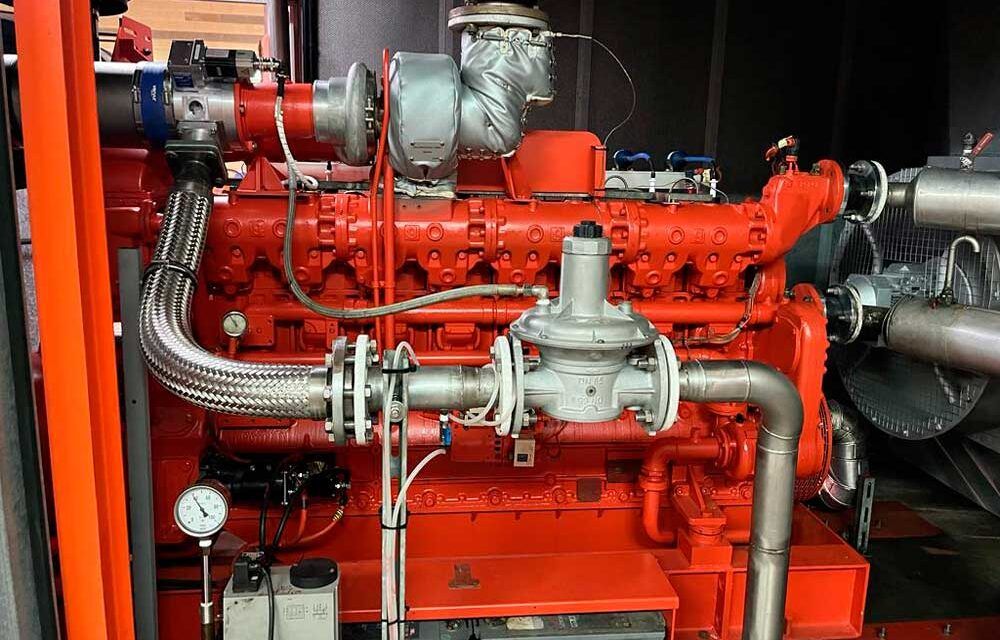

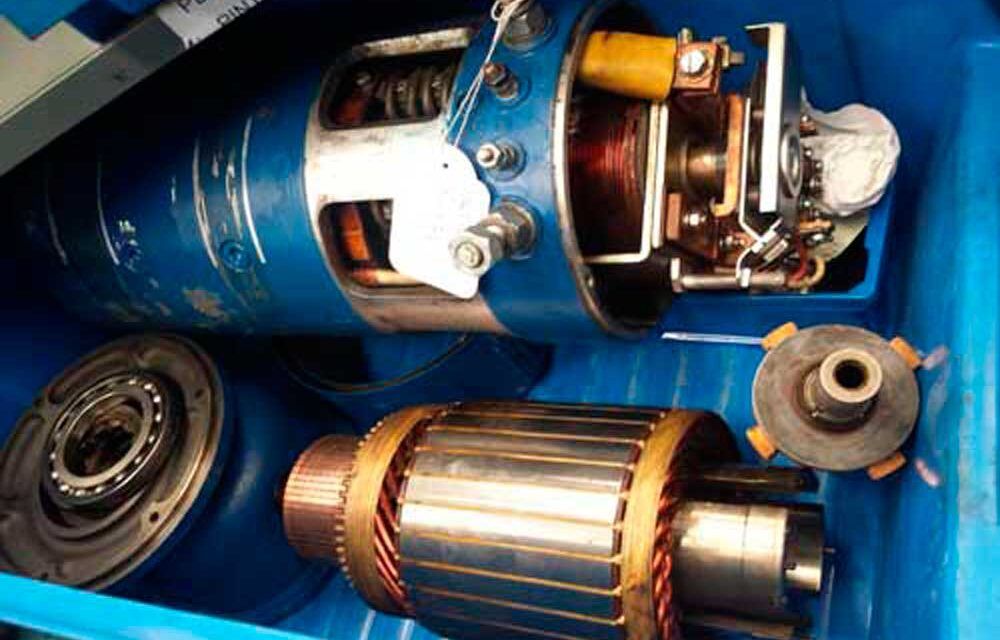

Oil cooler reconditioning with Deutz Mwm, Jenbacher and Guascor spare parts

This week at RS Motor, a new refurbishment job for cogeneration engine components has been carried out. On this occasion, it involves the oil cooler of a Deutz MWM engine which is refurbished with spare parts for Deutz-MWM engines. MAINTENANCE OF THE OIL COOLER WITH SPARE PARTS FOR DEUTZ-MWM, JENBACHER OR GUASCOR ENGINES These maintenance...