As a company specialised in DEUTZ / MWM and Jenbacher engines, this time we would like to show you that we are also experts in GUASCOR engines, both diesel and gas. RS Motor can carry out any type of preventive engine overhaul and corrective maintenance on GUASCOR engines both “in-situ” at the customer’s plant and at RS Motor’s facilities.

On preventive maintenance, from E1 to R3 (Overhaul), the RS Motor team can solve any problem using always original spare partsfor Guascor engines (genuine and OEM). After several years of experience, many of our customers trust us to repair any of their GUASCOR engines.

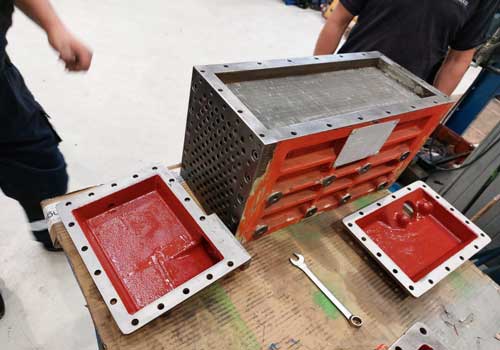

The reconditioning of cylinder heads, intercoolers, water pumps, starters, connecting rods, actuators, etc. is our daily work. But the major maintenance to be carried out on Guascor gas engines, also known as R3 maintenance, is one of our specialities.

Commonly, this type of preventive maintenance is carried out every 50,400 hours of operation (whatever the type of gas the engine consumes). Specifically this week we have been able to carry out this type of Overhaul at RS Motor’s facilities, where the execution time of the work at RS Motor to completely finish the R3 was 1-2 weeks.

The main repairs, replacements or overhauls that were carried out were as follows:

- Replacement of the main bearings.

- Replacement of oil pump and water pump.

- Replacement of lubricating oil filters.

- Replacement of spark plugs.

- Replacement of pistons and liners.

- Reconditioning of connecting rods, with renewal of connecting rod foot bushes and bolts.

- Reconditioning of cylinder heads.

- Checking the condition of the engine block, crankshaft and camshaft.

- Replacement of valve tappets (tappets).

- Turbocharger replacement or standard overhaul.

- Standard overhaul of generator/alternator.

- Intercooler replacement.

- Replacement of spark plugs, ignition coils and ignition cables.

- Renew oil filters and air filters.

- Renew torsional vibration damper.

- Replacement of starter/starter motor.

- Renew thermostats.

- Complete priming.

- Complete painting.

- Packing for subsequent shipment to the customer’s plant.

In conclusion, these are the tasks that make up an Overhaul or R3 maintenance of a Guascor engine. As we mentioned before, it should be noted that this maintenance can be carried out “in situ” at the plant if the customer does not wish to remove the engine, or if the downtime available is too short.

We would like to show you a series of images of the work process described above, which requires discipline, methodical processes, teamwork and tools of the highest quality with the inspection regulations complied with.

We are waiting for you, we want you to trust RS Motor for the supply of spare parts for Guascor engines , as well as for reconditioning any part of the engine, or even to carry out all the necessary preventive/corrective maintenance.

So, if you have a Guascor / Siemens engine and you want to buy parts or hire the best alternative service to the official brand to carry out major maintenance, call or write to RS Motor wherever your engine is.

Many customers have already worked with us, ask for your quotation and we will contact you as soon as possible to offer you the best options to suit your needs for both GUASCOR and DEUTZ / MWM engines. We are waiting for you.

For more information, visit our website www.rsmotorps.