One of the main activities carried out by Rs Motor is the performance of preventive maintenance steps included in the scope of the Manufacturer’s Maintenance Plans.

Overhaul of Jenbacher engines, Deutz-Mwm, Caterpillar, Guascor, Rolls-Royce, Scania or Iveco, are some examples of industrial engine manufacturers on which Rs Motor carries out this type of action.

The technical service of Jenbacher engines is one of the main activities of RS Motor since 2011. In order to give a quick response and to be able to offer the most competitive service to the customer, Rs Motor has a wide range of spare parts in stock.

In addition to all this, RS Motor has in stock reconditioned exchange equipment such as intercoolers, cylinder heads, connecting rods or oil coolers. The availability of this equipment makes it possible to shorten the execution time of preventive works of great scope (60.000 hours, 40.000 hours, 30.000 hours and/or 20.000 hours), making Rs Motor the best alternative to the official service.

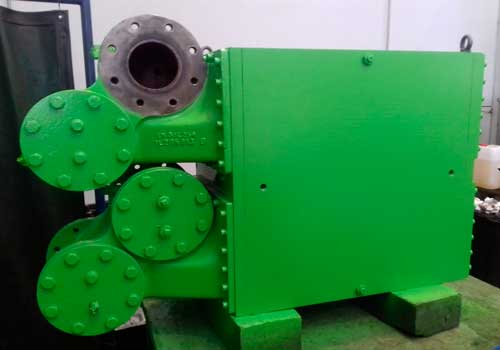

This week we are showing you the first of the many comprehensive maintenance jobs that RS Motor plans to carry out this year. This time, it is a 30,000 hours maintenance on a Jenbacher 616 natural gas engine.

The following is a summary of the main tasks carried out in the RS Motor workshop for this maintenance step:

- Disassembly of all engine block components.

- Checking for cavitations or damage to the block.

- Cleaning AND reconditioning of the intercooler.

- Disassembly of cylinder heads and external mechanical cleaning of the same and subsequent assembly of cylinder heads on the engine.

- Replacement of the actuator linkage ball joints.

- Replacement of the gas injector valves.

- Replacement of the pre-chamber tips.

- Replacement of the main bearings.

- Replacement of the complete pistons.

- Replacement of valve tappets (tappets).

- Replacement of cylinder liners.

- Overhaul of high voltage connections and wiring.

- Replacement of complete connecting rods.

- Replacement of connecting rod head bearings.

- Checking camshaft dimensions and tolerances.

- Camshaft bushing inspection.

- Standard reconditioning of turbocharger.

- Replacement of consumable parts (air and oil filters).

- Cleaning of battery connection terminals.

- Overhaul of starter motor.

- Replacement of main oil pump.

- Replacement of circulating water pump.

- Checking the state of the distribution.

- Check of pre-lubrication pump.

- Standard overhaul of alternator with bearing replacement.

- Standard overhaul of plate cooler.

- Replacement of throttle shaft.

- Complete engine reassembly.

- Connection, starting of the engine and check of operation and parameters.

- Prior to start-up, all auxiliaries are checked to verify the absence of anomalies.

- Checking vibrations and regular running.

- Checking control devices, shutdown systems, control functions and indicator lights.

- Checking engine bleeding.

Once the work in the workshop has been completed, our technicians go to the customer’s plant to carry out the engine start-up. When starting the engine, one of the most important things is to make sure that all the engine parameters are within their nominal values.

Now that you have seen another example of RS Motor’s technical capability during maintenance work, do not hesitate to ask our team for a quotation for any type of work or supply Jenbacher gas engine overhaul of Jenbacher spare parts (genuine and/or OEM).

For more information, please write to social@rsmotor.es.