Over the years, RS Motor has received a multitude of components related to the world of cogeneration and the marine market for reconditioning and repair. As a company with an excellent track record in the Jenbacher gas engine overhaul and Deutz- Mwm engine overhaul, there is no doubt that our customers rely on our services for the repair of their cylinder heads, whatever type of engine they have.

The cylinder head is a vital component when it comes to obtaining a good performance of the group, it is the part responsible for ensuring the closure of the cylinders and the intake and exhaust valves are housed here, it is an independent and removable part bolted to the block of the cylinder seats whose union is made watertight by the so-called cylinder head gasket. They are carefully cooled by large water chambers surrounding the combustion chambers and exhaust ducts.

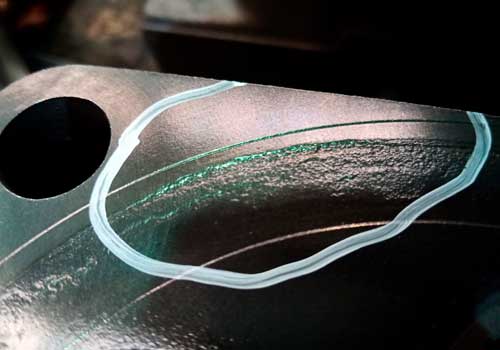

Cylinder heads are subject to high mechanical, chemical and thermal stresses due to gas residues, water, etc. Despite this, cylinder head shells suffer from wear on their surfaces in contact with the cooling ducts and to a greater extent in the area of the combustion chambers where the cylinder heads can show an excessive degree of corrosion caused by erosion through chemical reactions, which causes mechanical wear by removing a protective film from the cylinder head surface. Erosion corrosion generally has the appearance of small smooth pits and is intensified under conditions of high speed, turbulence, shock, etc.

Eroded areas:

- Erosion in the cylinder head seat area.

- Erosion in the bolt area.

- Erosion in the intake face area.

- Erosion in the exhaust face area.

Solution for repairing cylinder heads with erosion:

At RS Motor we have a specialised repair workshop to remedy such erosions or any failure derived from this phenomenon presented in any type of cylinder head shell. Below, we mention the processes carried out for their repair:

- Visual inspection of the surfaces, cleaning of the remaining dirt and welding in the areas with severe erosion wear.

- Machining of the surfaces where they were subjected to welding, the excess material is removed until the desired total plane is achieved.

- Mechanical rectification to correct and perfect the affected surfaces.

- Final parallelism control on the grinding table to verify that the mechanical repair process has been satisfactory.

It should be noted that, apart from the problems derived from erosion, we also find minor failures in the cylinder heads due to wear and tear after working hours, or replacement of the spare parts that make up the cylinder head. These failures are usually the lodgings of the cylinder head sleeves or cylinder head studs against the block where the threads are in poor condition.

Solution for repairing cylinder head threads:

- Rework the thread using a threading tool and clean the housing.

- If the thread is unrecoverable, it is necessary to insert a helicoil which is fixed in the hole to form an internal spiral where the screw, stud, sleeve, etc. will be fitted.

After the brief description of the tasks performed, we share some of the most representative images of the cylinder head repair work where you can see its professional finish, do not hesitate to bring your cylinder head shells for repair and do not forget to also consult our Jenbacher gas engine overhaul and Deutz- Mwm engine overhaul.

Here at RS Motor we offer you immediate, efficient and long-lasting solutions, prioritising the highest quality in the execution of our work. Our company is able to help you whatever your conditions are.

For more information, social@rsmotor.es